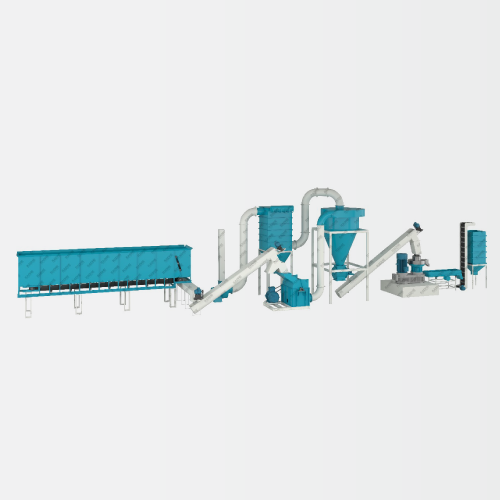

Fully Automatic Biomass Pellet Production Line

Our Fully Automatic Biomass Pellet Production line is a cutting-edge solution designed for efficient, large-scale production of high-quality biomass pellets. Engineered for performance, durability, and minimal manual intervention, this system offers a seamless, end-to-end process – from raw material intake to final pellet packaging.

The Fully Automatic Biomass Pellet Manufacturing Unit is equipped with a complete automation system that controls every stage of the production process, from raw material intake to final pellet packaging. It offers exceptional output efficiency, designed for continuous 24/7 operation while maintaining consistent pellet size, density, and quality. This unit is highly versatile, capable of processing a wide range of biomass materials such as sawdust, wood chips, rice husk, straw, and other agricultural or forestry residues. Its energy-efficient design helps reduce operational costs by optimizing power consumption throughout the production line. The user-friendly, PLC-based control panel allows for easy monitoring and adjustment, ensuring maximum productivity with minimal manual intervention. Built with robust, industrial-grade components, the unit is designed for long-term, heavy-duty use and can be customized to suit specific production requirements or raw material types.

Perfect for businesses and industries looking to convert agricultural and forestry waste into eco-friendly fuel pellets for domestic use, industrial boilers, biomass power plants, and export markets.

Technical Specifications

| SPECIFICATION | DETAILS |

| Production Capacity | 2 Tons per Hour (Customizable) |

| Raw Materials Supported | Sawdust, Wood Chips, Rice Husk, Straw, Bagasse, Agricultural Waste |

| Pellet Diameter | 6mm to 12mm (Adjustable) |

| Moisture Content for Input | ≤15% (Material drying system can be added for higher moisture content material) |

| Main Equipment Included | Feeder, Hammer Mill, Dust Collector, Pellet Mill, Cooler, Screener, Packaging Unit, Conveyor Systems, Air compressor |

| Automation Level | Fully Automatic with PLC Control |

| Land Area req. for Machinery Installation | 2200 Sq feet (100L X 22W X 18H) |

| Power Consumption | 190 – 225 kW (Depending on Configuration) |

| Voltage Requirement | 380V / 415V, 50Hz / 60Hz (Customizable) |

| Operator/Labor Requirement | 1 Operator + 1 Loader Driver + 2 Labor / per shift |

| Pellet Density | 1.1 – 1.3 g/cm³ |

| Cooling System | Counter-flow Cooler |

| Dust Control System | Cyclone Dust Collector / Pulse Jet Filter |

| Packaging Options | 50Kg Bag, 750 Kg Jumbo Bag |

| Installation & Commissioning | Included (On-site Support Available) |

| Warranty | 1 Year Standard |