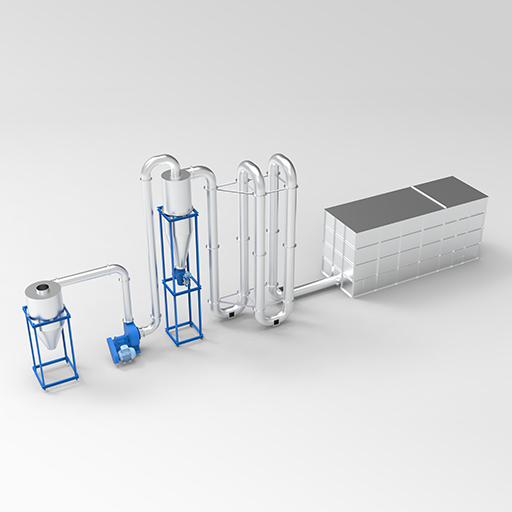

Flash Air Dryer (Tornado)

- Output Production Capacity: Up to 1500 Kg/Hr (Based on Input Moisture % Max. 30%)

- Input Moisture Percentage: 30%

- Output Moisture Percentage: 10%

- Water Evaporation Capacity: Up to 450 Kg/Hr

Dependable Output Capacity The output production capacity of our flash dryer is determined by the input material’s moisture percentage. If the moisture percentage exceeds 30%, the output production capacity will be proportionally adjusted to ensure optimal drying efficiency.

Advanced System Specifications

- Type of Dryer: Flash Type

- Dry Through: Hot Air

- System Pressure: Negative/Suction

- Fuel in Furness: Solid Coal (Briquettes/Fire Wood)

Efficient Technical Specifications

- Blower: 25 HP

- Rotary Air Lock Valve: 1 HP

- Screw Conveyor: 3 HP

Precise Atomization for Smooth Operation

- Feeding conveyor speed is controlled based on the cyclone outlet set point temperature for optimal performance.

- Servo control valve is adjusted according to the desired temperature for precise system operation.

Required Land Area & Size

- Length: Approximately 20 Feet

- Width: Approximately 15 Feet

- Height: Approximately 20 Feet

With our reliable flash dryer, you can achieve high output production capacity while ensuring efficient drying performance. Contact us now to learn more about our advanced drying solutions for your production needs.

The Advanced Features of Radhe Industrial Corporation’s Biomass Flash Air Dryer

- Extended travel length with Hot air for maximum drying efficiency.

- Precise and controlled feeding with complete atomization via VFD drive according to operating parameters.

- High-capacity ID Blower to ensure optimal airflow for drying.

- Servo control valve for precise mixing of fresh air to achieve desired input temperature from furnace.

- Effective dust collection system to mitigate dust pollution.

- Temperature sensors strategically placed at all required locations to maintain optimal atomization set points.