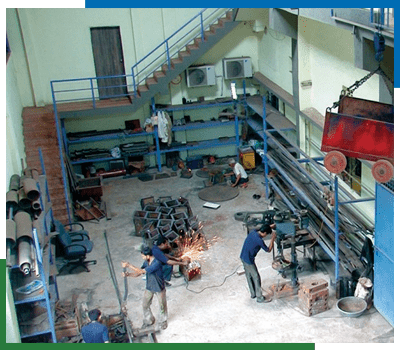

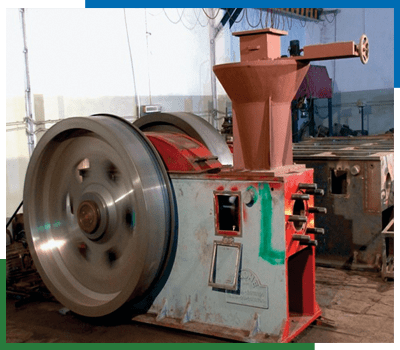

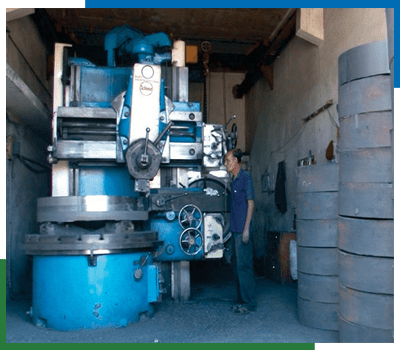

Assembly Department

This department is responsible for assembling different parts to create a final Machine. At Radhe Industrial Corporation, the Assembly Department puts together Biomass Briquetting Press Machines and Biomass Pellets Making Machines.