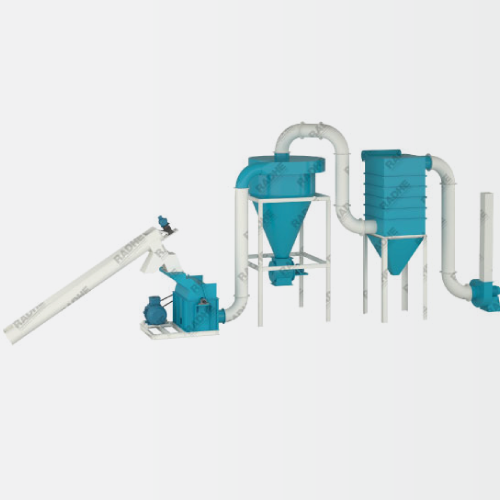

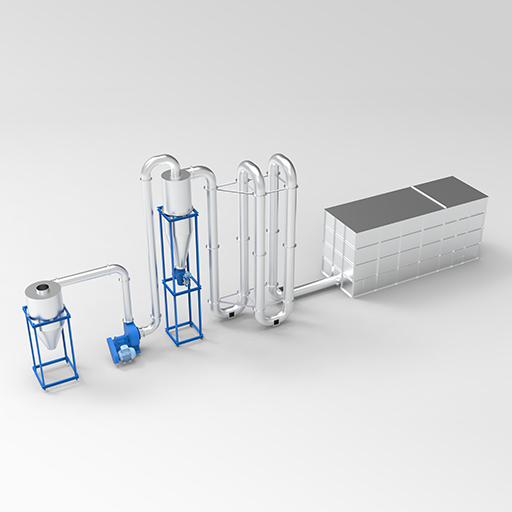

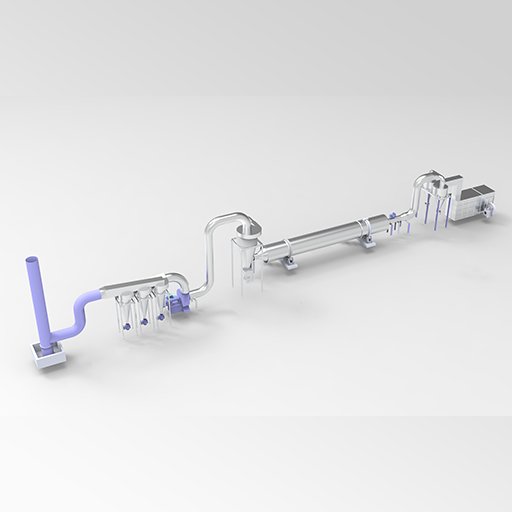

Our Hammer Mills are equipped with advanced technology and robust construction, ensuring durability and long-lasting performance. They are capable of handling various types of biomass waste, including wood chips, straw, stalks, corn stalks, peanut shells, and more. The crushing action of our Hammer Mills ensures that the biomass waste is reduced to a fine powder, which can be used for further processing or as raw material for other applications.

Our website provides detailed information about our Hammer Mills, including specifications, features, and applications. We also offer comprehensive customer support, including technical assistance and after-sales service, to ensure that our customers have a smooth experience with our products.

Whether you are looking to process biomass waste for animal feed, biofuel production, or other applications, Radhe Industrial Corporation’s Hammer Mills are the perfect solution. Trust our expertise and experience in manufacturing high-quality crushing equipment, and join the list of satisfied customers who have benefited from our innovative solutions. Experience the cutting-edge technology of Hammer Mills by Radhe Industrial Corporation and transform biomass waste into valuable powder with ease!

Technical Specifications

Our Hammer Mill, available in various models with different capacities, is designed to efficiently process biomass raw materials. The capacity options include:

- Hammer 1500: 1500 KG/HR

- Hammer 3000: 3000 KG/HR

- Hammer 5000: 5000 KG/HR

Input Raw Material (Biomass) Size (Length/Diameter):

- Maximum 100mm Length / 20mm Diameter

Output Raw Material (Biomass) Specification Size:

- Adjustable between 1mm to 15mm, as per requirements

Form:

- Uniform semi-powdery / powdery

Output Production Capacity

- 1500 KG/HR for Hammer 1500

- 3000 KG/HR for Hammer 3000

- 5000 KG/HR for Hammer 5000

Silent Features of Radhe Industrial Corporation’s Hammer Mill:

- Standard heavy-duty construction with applicable MOC (Material of Construction)

- Automatic load sensing and feeding control to prevent overloading of the main motor

- Separate removal of big stones to prevent damage to the mill

- Dust collector to prevent dust pollution after cyclone

- Various capacity models available to suit different production needs

Choose Radhe Industrial Corporation’s Hammer Mill for efficient and reliable biomass processing. Contact us to discuss your requirements and find the right model for your needs.